King Stella Group, a major Thai consumer goods manufacturer, is facing major problems in its production line for its top-selling gel air freshener. Production is insufficient to meet market demand, and the packing process is a major bottleneck that is causing production stagnation.

You May Also Like

With support from DENSO Lean Automation System Integrators (LASI), the company was able to efficiently transform its production by integrating IoT tools and implementing kaizen, resulting in a 167% increase in productivity and a reduction in cycle time to just 0.87 seconds per piece within a few months.

King Stella Group’s Challenges

- Production capacity is insufficient to meet market demand for air freshener gel.

- The packing process is a bottleneck that affects the overall production.

- Productivity is inconsistent as it depends on the skills of each individual employee.

- There are no clear work standards and the division of responsibilities is not systematic.

Lean Automation + IoT Tools: The Key to Success Data analysis with IoT tools

- Identify issues immediately by gathering and analyzing in-depth data.

- Visualize real-time performance, enabling accurate identification of bottlenecks and improvement points.

Improving production efficiency

- Improved the entire packing process

- Using Karakuri Automation, one employee can perform multiple tasks simultaneously.

- Create standardized work manuals to help new employees learn skills faster.

Measurable results

- Productivity increased by 167% in just a few months.

- Reduce cycle time to only 0.87 seconds per piece.

- Employees have improved problem-solving skills and Kaizen capabilities.

- Employee motivation is increased because they can work more efficiently than before.

- New employee training is faster and standardized.

Success Case Study: From Bottlenecks to Efficient Production

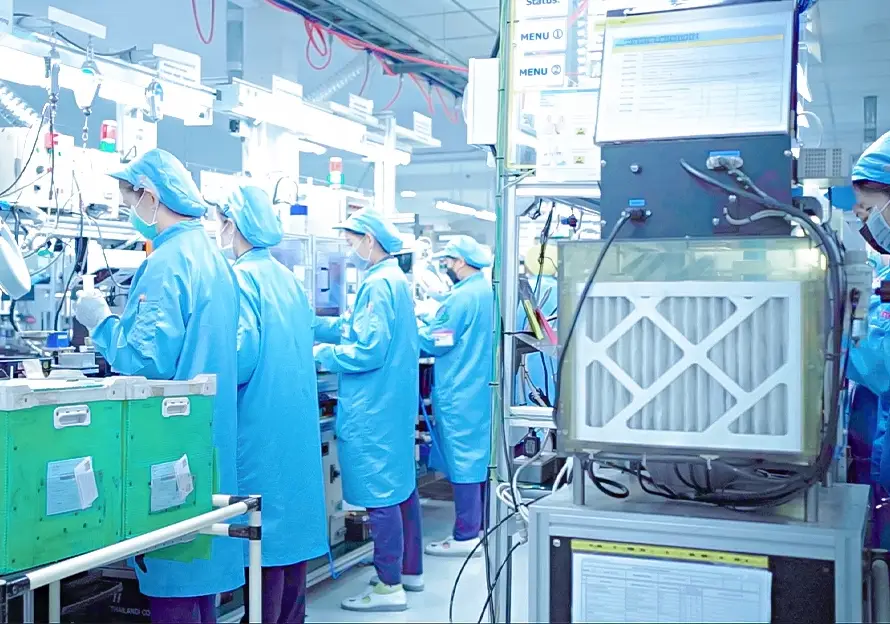

King Stella Group’s air freshener gel production line has two main steps:

- Mixing of raw materials

- Packaging and packing

The main problem lies in the packing process, which requires manual labor around the table to assemble the top and bottom covers, insert the paper sleeves, and pack the cartons. This task depends on the skills of each worker, resulting in inconsistent speed and quality.

By applying Lean Automation and IoT Tools, the air freshener gel production line is back to peak efficiency.

Summary: King Stella Group towards the future of intelligent manufacturing

The success of King Stella Group demonstrates that the combination of Lean Automation, IoT Tools and Karakuri, combined with a Kaizen culture, not only increases productivity but also creates a sustainable and standardized work system.

- Productivity increased by 167%

- Reduce uncertainty from labor skills

- Employees are motivated and engaged in the development process.

This is another case study proving that technology integration and continuous improvement are the keys to future competitiveness in the manufacturing industry.