Sriborisuth Forging Technology elevates automotive parts production with Lean Automation

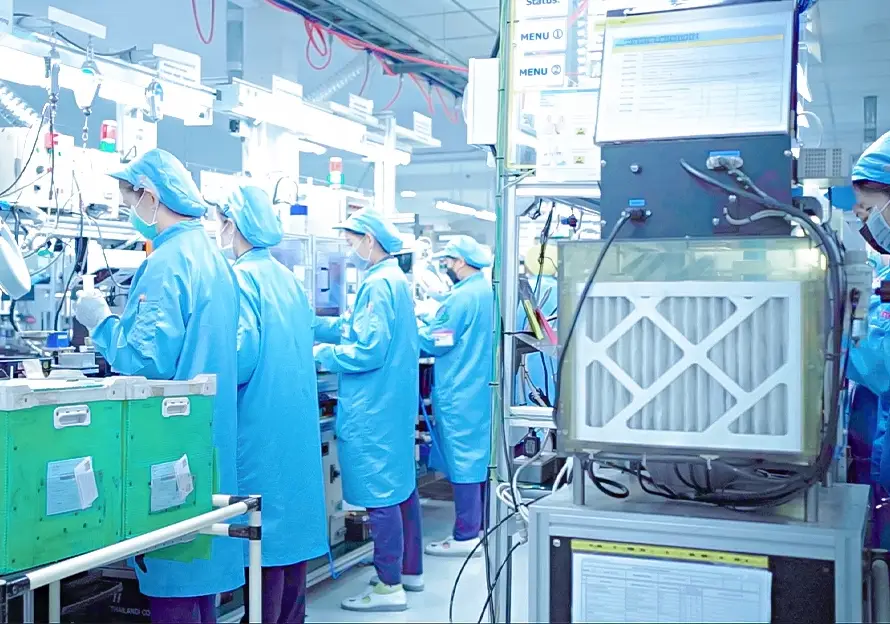

Sriborisuth Forging Technology Co., Ltd., an automotive parts manufacturer established in 2010, faced significant problems in its production line such as workload imbalance, inaccurate demand forecasting, and complex production lines, as well as a shortage of production labor.

You May Also Like

To address these issues, the company joined DENSO’s Lean Automation System Integrator (LASI) Program and applied the knowledge gained in practice in the factory, resulting in significant results in both Productivity Improvement and Work Loss Reduction.

Sriborisuth’s Challenges Before Lean Automation

- Workload imbalance reduces productivity.

- Inaccurate demand forecasts result in excess inventory.

- Employee movement times and working methods are inefficient.

- The flow line is too complex, causing a waste of time and resources.

Lean Automation: The Shift from Learning to Doing

Sending engineers to learn at DENSO’s LASI (Lean Automation System Integrator) was a turning point.

- Gain true knowledge and concepts of Lean Automation.

- Use robots for high-speed operations (2.5 seconds/piece).

- Develop high-speed forging dies to reduce work loss.

- Collaborate between Production Engineers and System Integrators (SIers) by sharing problems, improving and fixing them together.

The visible results of Lean Automation

- Productivity increased by 30% with Robot Automation

- Cycle Time 2.5 seconds/piece for high speed operation.

- OEE (Overall Equipment Effectiveness) increased to 85%.

- Reduce the number of workers in the production line by 3 people/line.

- Reduce the heavy and complex workload of employees by letting robots do the work instead.

- Get an automated system that not only installs but actually helps improve productivity.

Inspirational quotes

One of the points that made the Sriborisuth team change their perspective was a quote from a professor from LASI, Fumio Kojima:

“If automation doesn’t increase productivity, it’s meaningless.”

Future: Expanding Lean Automation to other production lines

With the tangible results, Sriborisuth intends to expand the use of Lean Automation to other forging lines to create a sustainable and highly efficient production system.