Nakamura Electric Industry elevates production with Factory IoT and Kaizen culture

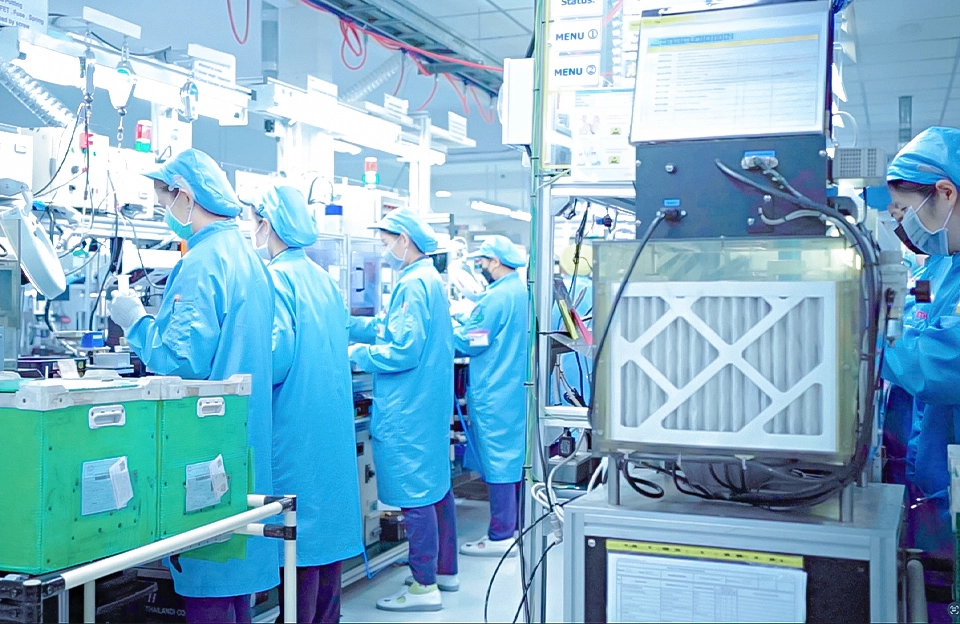

Nakamura Electric Industry Co., Ltd., a manufacturer of air conditioner resistors, is moving towards in-house production to gain competitive advantages both domestically and internationally. A key turning point is the adoption of DENSO Factory IoT to analyze and improve production lines, while deepening the Kaizen culture within the organization.

Challenges of producing key parts in-house

You May Also Like

In an era of intensifying global competition, increasing production productivity is an urgent necessity. Nakamura Electric Industry faces several challenges, including:

- Improving production productivity to meet global market demand

- Beginning to produce core parts in-house instead of relying solely on assembly

- Create an efficient production system for new products

- Identifying areas for improvement in the existing production line

Factory IoT: The key to increasing manufacturing productivity

By implementing Factory IoT, Nakamura Electric Industry was able to analyze production data and clearly see long-hidden problems such as:

- Identify the bottleneck of the production line.

- See the difference between the performance of old and new employees.

- Use insights to transfer skills and improve manufacturing processes.

The result is that the company can increase production productivity in a short period of time, even in processes with which it has no previous experience.

Examples of improvements with Factory IoT and Kaizen

After completing the improvement of our Power Transistor production line, we immediately began developing the resin molding process, which has resulted in the following remarkable results:

- Reducing production line downtime from grease filling

Problem: Previously, workers had to take time off work to refill grease, causing frequent production line stops.

Solutions: After analyzing Factory IoT data, they discovered that this problem was significantly impacting production times. The company developed a new device that allowed for faster grease replenishment and adjusted the process so that another employee would have a spare cylinder ready in advance.

Result: Grease refill time reduced by more than 70%.

- Improving the Soldering Process (Terminal Soldering)

Problem: Video analysis reveals how employees with different experience work, creating a gap in the time spent on tasks.

Solutions: Standardize work and adjust preparation procedures.

Result: Reduced process variation and increased production stability.

- Air Blowing

Problem: The blowing process depends on the individual operator’s method. Sometimes it is done more than necessary, resulting in waste due to overprocessing.

Solutions: To solve this problem, we have implemented an automated system that can blow air at set times with the push of a button.

Result: Standardized work and time reduction, resulting in a 60% reduction in cycle time.

4. Terminal Insertion

Problem: Previously, inserting complex terminals had to be done one piece at a time by hand, which was time-consuming and prone to errors.

Solutions: We developed a new jig based on video analysis that allows for inserting four terminals at a time.

Result: Reduced operation time from 21 seconds to only 17 seconds.

5. Training new employees with Factory IoT

We’ve implemented Factory IoT to develop the skills of new employees. The system displays comparison data between experienced and new employees via video recordings, allowing new employees to see the differences, understand proper work practices, and improve themselves in a shorter period of time.

Kaizen Culture: The Foundation of Sustainable Development

The use of Factory IoT not only solves immediate problems but also drives organizational change by creating a Kaizen culture that encourages employees at all levels to participate in proposing improvements, resulting in continuous and sustainable development.

Summary: Factory IoT and Kaizen are transforming manufacturing.

A case study of Nakamura Electric Industry shows how the implementation of Factory IoT and Kaizen concepts helped the company

- See problems that were never clearly identified before

- Increase production productivity in a short period of time

- Create an effective skills transfer system and work standards

- Laying the foundation of a culture of continuous improvement

This is an example of an organization that turned a challenge into an opportunity and used manufacturing data analytics to drive improvement.