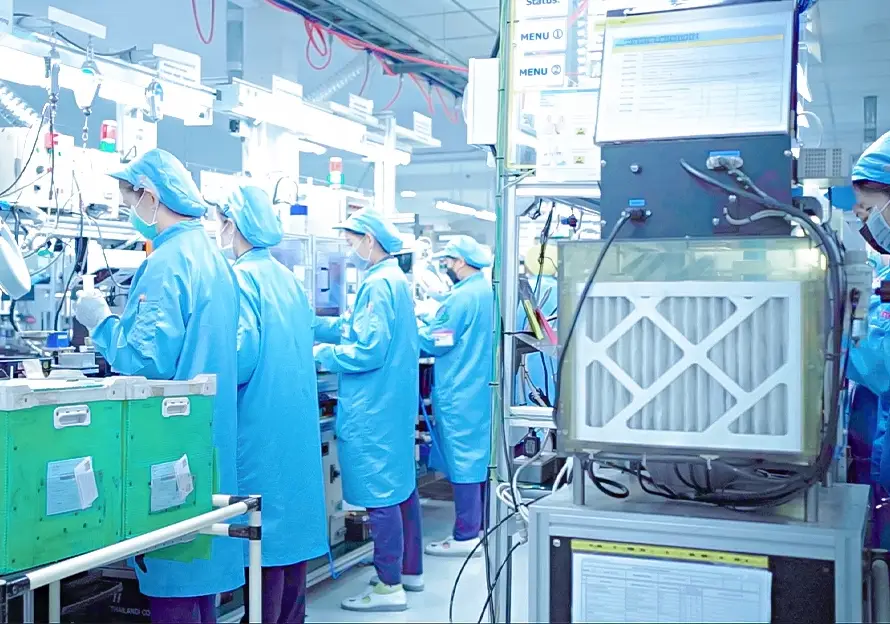

Ennovie transforms jewelry manufacturing in Thailand with Lean Production and IoT Technology

You May Also Like

Ennovie, a Thai manufacturer of high-quality jewelry that exports to leading global brands, faced a major challenge due to rapidly increasing demand. The problem was how to increase production capacity without losing the craftsmanship that is at the heart of jewelry making.

The answer lies in going back to the basics of Lean Production, combining it with the use of IoT technology to analyze production in detail and develop Kaizen, along with step-by-step automation, which has increased production efficiency from 16% to 65%.

Customer Satisfaction·Evaluation

Challenges in jewelry production

- Market demand is increasing rapidly, requiring a choice between increasing labor or increasing efficiency.

- 80% of production has already been mechanized, but the remaining 20% still requires skilled labor and is difficult to automate.

- Full automation is not possible in the jewelry industry.

- Production efficiency is lower than expected and urgent improvements are needed.

Lean Production + IoT: The Power of Change

- Motivation

It started with the introduction of a Profit-Sharing Program to motivate employees to participate in improving their work.

- Systematic analysis of production processes

Use VDO Analysis and IoT Technology to collect real data, check performance consistency and identify hidden issues.

- Returning to the Basics of Lean Production

Instead of rushing to full automation, Ennovie chose to

- Develop step-by-step improvements (Step-by-Step Automation)

- Reduce losses such as Management Loss, Start-up Loss, Inventory Loss

- Create a data-centric system to benefit employees, management, and the company.

Clear results

- Production efficiency increased from 16% → 65%

- Reduce losses in administration, start-up and inventory management.

- Employees have a better understanding of their work, are more skilled at problem-solving and process improvement.

- The company can respond to market demands faster without sacrificing quality and craftsmanship.

The new future of jewelry production

Ennovie’s success demonstrates that combining Lean Production, IoT Technology, and a Kaizen culture can help craft-driven industries continue to evolve into Smart Factories.

This is an example of using data analytics and continuous improvement to balance technology and craftsmanship in the modern manufacturing world.

“Lean Production in Jewelry”, “IoT Technology in Manufacturing”, “Improving Jewelry Production Efficiency”