Asian Alliance International, one of Thailand’s largest food processing companies, is facing labor shortages and rising labor costs as market demand continues to grow. To overcome this crisis, the company is taking a new approach by introducing lean automation and robotics into its production lines.

You May Also Like

The result is that one robot can replace up to 11 workers and increase production efficiency by 150%, which is a major change for Thai food factories.

Challenges in the food industry

- Labor shortages and rising wages

- Traditional production methods are unable to meet the growing demand.

- The need to invest in efficient and cost-effective automation systems

- The challenge of implementing Kaizen while using robotic technology

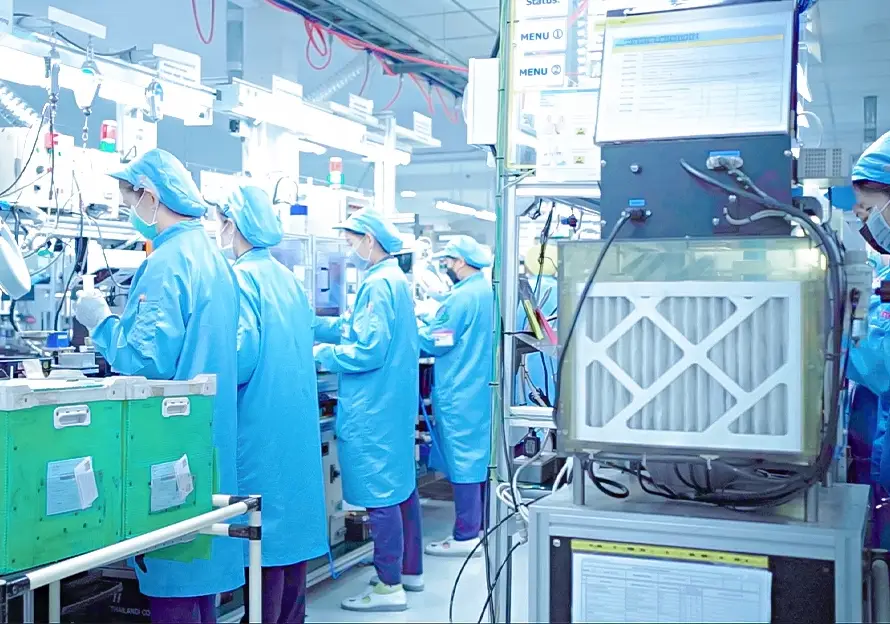

Lean Automation: A Turning Point for Asian Alliance International DENSO's meeting with LASI (Lean Automation System Integrators) in 2018 was a turning point for Asian Alliance International to turn a crisis into an opportunity. DENSO has introduced a Lean Automation approach that addresses both cost reduction and efficiency gains by combining Kaizen and robotic automation.

Integration of Kaizen and Robotic Automation

Integration of Kaizen and Robotic Automation

Step 1: Improve the process with Kaizen

- Optimizing product orientation, positioning, picking and placement

- Work is more standardized and efficient.

Next step: Use automated robots in the packing process.

- The robot can pick up products and arrange them into boxes accurately and quickly.

- Reduce the risk of lost or damaged goods

- Improved robot movement to ensure continuous and stable operation.

Results from Lean Automation and Intelligent Robots

- 1 robot = 11 people, clearly solving the labor shortage problem.

- Increase production productivity by 150% to meet market demand

- High speed and efficiency: Cycle time is only 0.5 seconds/piece and robot working efficiency is 95%.

- Pre-shipment inspection time is only 1 day left.

- Employees and engineers have improved problem-solving skills and development proposals.

Factory of the Future: Humans and Robots Working Together

This achievement not only solves the labor shortage problem but also leads Asian Alliance International to become a Smart Factory that integrates humans and robots.

The company is currently planning to expand Lean Automation to 26 new projects to create more efficient production lines and continuously develop the capabilities of its employees.

Summary: Lean Automation is transforming the Thai food industry.

A case study by Asian Alliance International shows how the application of Lean Automation and robotics, along with the creation of a Kaizen culture, can help companies:

- Dramatically increase production productivity

- Reduce reliance on labor and solve the problem of human shortages

- Creating long-term competitiveness in the global market

This is an example of turning a crisis into an opportunity with technology and continuous improvement in the Thai food industry.